M2 is a HSS drill bit compound that has high wear resistance and is used in all general steel drilling applications involving standard / mild / black steel. Depending if you are drilling mild steel or hardened steel will determine whether you purchase M2 or M35 drill bits: The most popular HSS drill bits fall into the following two categories: M2 & M35. The Best HSS Bit Depends on your Application Perhaps the most popular tip design has a 135 degree “split point” design giving accurate starting without the use of a center punch. The design of the cutting tip is also very important. The types of HSS Steel used in Drill Bits are below: This property allows HSS to cut faster, and at room temperature HSS grades generally display high hardness. All of these HSS drill bits are superior to carbon steel in that they can withstand higher temperatures without losing their temper (hardness). The table below outlines some of the more popular answers as to the second question: What material are they made from. The very best drill bits are “Fully Ground” which means the bit was ground out of the one piece of raw material, and as such are very precise and strong. There are three questions to ask when you are choosing a drill bit for a job: How is it made, what material is it made from, what is the design of the cutting tip ?Īll good drill bits for drilling all types of steel fall under the category HSS or High Speed Steel drill bits. How do you choose the right drill bit for the job?

Flat Twist Wheels - Angle or Bench Grinder.

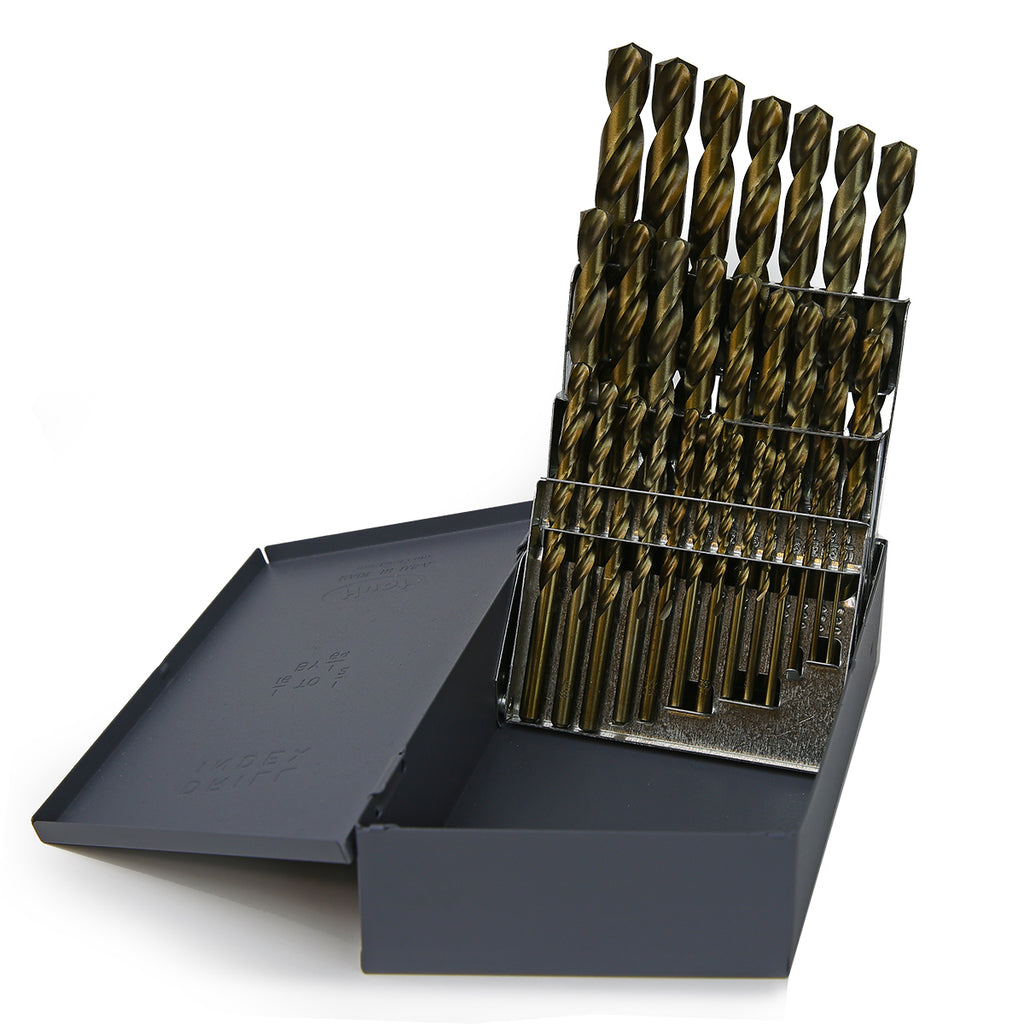

Surface Conditioning Quick Change Discs, 2″.Surface Conditioning Quick Change Discs, 3″.3″, 75mm Ceramic Strip Disc (Quick Change Tool).3", 75mm Strip Disc (Quick Change Tool).Accessories Included Case, steel index Material M35 Cobalt Maximum Diameter 1/2 in.

0 kommentar(er)

0 kommentar(er)